THOMASBERG, LOWER AUSTRIA — In a wooded valley an hour south of Vienna, a modern, glass-walled, wood-sided restaurant called Franz spans the babbling River Pitten. This restaurant links together two sides of the production and design facilities belonging to F/LIST, a family-owned Austrian company that produces some of the most jaw-dropping interior innovations across the passenger experience.

Franz is named for the grandfather of the current chief executive officer Katharina List-Nagl, who is the third generation of Lists to run what started as a rural Austrian cabinetmaker 75 years ago.

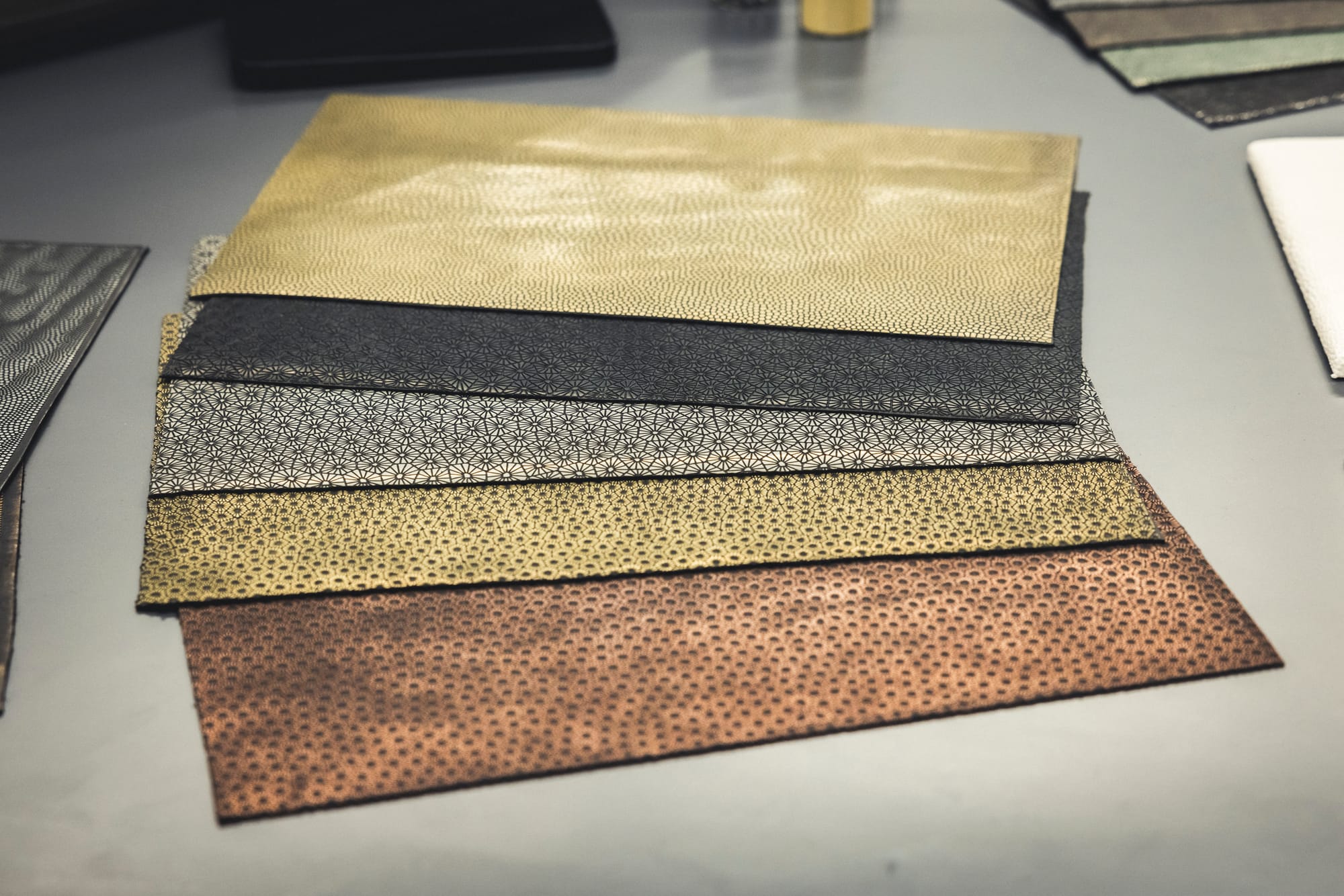

Today, F/LIST’s products are genuinely stunning, both as raw materials and in the way that the company is starting to incorporate them in innovative new ways.

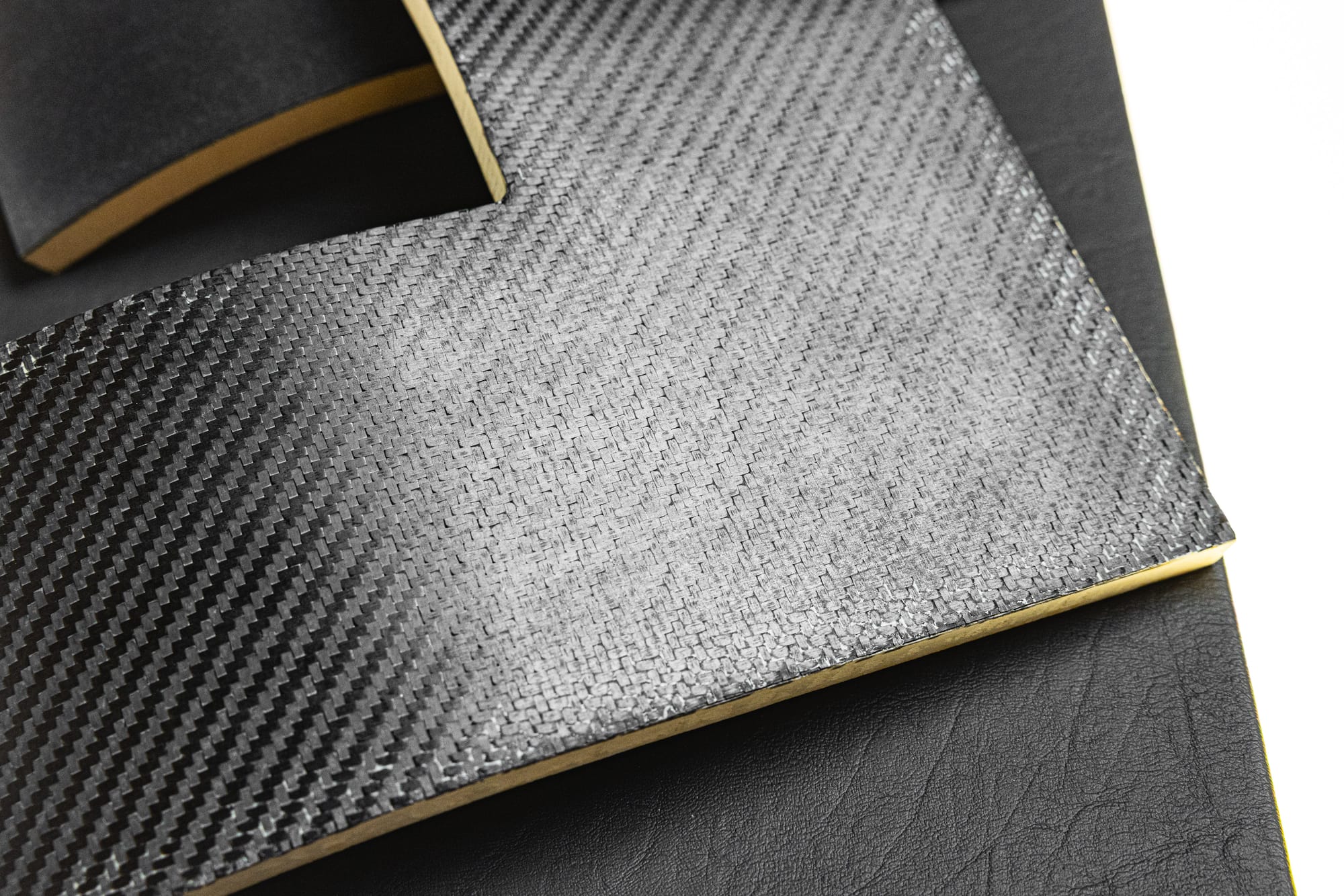

Beyond its expertise in wood veneers and thin stone layering for which it is known, F/LIST is rocketing ahead of the pack, combining natural elements like those woods and stones into high-technology engineering, integrating design and materials science to impressive effect.

Perhaps the most impressive of these integrations so far is Shapeshifter. Indeed, it’s rare that a product at the Aircraft Interiors Expo spurs anything like the kind of “wow” reaction that F/LIST’s Shapeshifter technology created. Under its engineered stone surface are small actuators, allowing the surface to quite literally change shapes.

The first Shapeshifter implementation F/LIST showed off, at the 2025 Aircraft Interiors Expo, was a side console with built-in wireless charging.

On placing the phone on the surface, Shapeshifter actually changes the shape of what looks like a fully flat white mosaic-effect surface, retracting to cradle the phone into the position for the most efficient wireless charging option — and simply looking incredible.

To your author’s mind, this was the most innovative thing in any hall of AIX this year, and the trajectory of the Shapeshifter technology that F/LIST has in mind feels like it almost defies physics.

A second implementation is a business jet or first class tray table, today often a clunky and space-hungry affair with heavy mechanical support.

F/LIST’s innovations mean that the natural wood of the table surface and structure can be engineered to be flexible enough to essentially unroll automatically, seemingly appearing from nowhere inside a side console.

Another implementation is a side credenza, with curved wraparound wood surfaces creating genuinely impressive furniture with real space-saving functionality, without compromising on aesthetics.

And F/LIST has plans for more. Much as the restaurant spans the River Pitten, joining the two parts of the company’s production site, the 2024 opening of the F/LAB innovation lab on the Pitten’s eastern banks joins together design and production to enable what List-Nagl calls a collaborative “co-creation” process with designers, interiors manufacturers, airframers and customer airlines.

Collaboration — and the need to improve and increase it throughout the passenger experience supply chain — is at the forefront of many minds in the industry, and was certainly a consistent theme at the RedCabin Business Jet and VIP Interiors Innovation Summit In Vienna (around which, full disclosure, summit sponsor F/LIST hosted The Up Front for the visit its Thomasberg headquarters).

The summit, a counterpart to RedCabin’s well-regarded and informative twice-yearly airline interiors summits, had surprising read-across to the commercial world, perhaps more than I’ve seen before.

It’s not just that F/LIST’s materials and finishes are impressive. It’s that the company has clear ambitions to be part of the production value chain as it transforms those materials into genuinely jaw-dropping products, and is positioning to be at the heart of the collaboration process with customers — and the rest of the supply chain — to do so.

Airlines want to seduce private aviation customers into their first class — and even business — cabins

As the premiumisation trends within the cabin combines with an increasing demand for luxury at the front of the aircraft, it seems natural to turn to a company that has spent much of the last twenty years becoming a well-known part of the business jet interiors business.

“Airlines have a high interest to get the business aviation customers on the airline, so they want us to give them our experience on what the private and business aviation customers are looking for,” List-Nagl explains. “We have those insights from the designers, and again, coming from the yachting side, we help them create that luxury environment.”

F/LIST’s goal, she says, is “to bring all the high quality materials, the surfaces, the natural materials, which haven't been very common in commercial aviation, into commercial aviation — to make the first and business class environment as enjoyable as a private airplane.”

Of course, there are inherent differences between the requirements for creating cabins in private jets and those in commercial airlines, but perhaps not as many as there once were.

“The private aviation side used to be single owners of an aircraft — now we're talking to many fleet customers,” List-Nagl says, citing fractional ownership and flexible providers like Flexjet, VistaJet and NetJets as examples. “Utilisation… is much higher, much tougher than it used to be, so we already started developing surfaces and new decorative elements that are able to deal more easily with heavy use. This is also a very good starting point now for offerings in commercial aviation, because everything needs to be easily maintainable. It needs to be highly durable.”

Given that a key difference between private jets and airliners is the standard of safety certification onboard — and that certification problems have tripped up no few aircraft interiors programmes in recent years — this is a hot topic when F/LIST talks to cabin designers and creators in the commercial world.

“The main difference between our approach in business and commercial aviation is discussions about certification,” List-Nagl says. “At the end, the topics are pretty much the same, especially with the design teams: it's all about offering them as many opportunities and possibilities in terms of new materials, in terms of new design opportunities.”

On the commercial side, “it’s all about reliability, it's about use case, it's about how frequently or how heavily the materials are being used — it's more the use case that is being discussed,” she notes.

F/LIST’s manufacturing scale matches the “world’s largest cottage industry” feel of commercial aviation interiors

I’ve often referred to the seats and cabin interiors world as the “world’s largest cottage industry”, given the comparatively small volumes and manual production lines on which seats, inflight entertainment systems, cabin elements and so on are built.

Little to none of this is on the scale of much more than light industry, and F/LIST’s factory floor is no different: it feels similar in size and scale to other relatively low-volume parts of the commercial aviation interiors industry like seatmakers, materials suppliers, and other links in the supply chain.

Perhaps there is more of an aroma of wood than in most interiors businesses, but at its core F/LIST’s facilities are comprised of a series of light industry buildings that have expanded over time, filled with stocks of raw materials, the machines that transform them into product, and the people with the expertise to make it happen.

Employees — including many almost impossibly young-looking apprentices — get on with their jobs, chatting and joking with colleagues as they circulate around the shop floor, obviously recognising (and on a first-name basis with) the management team showing us around.

The design space F/LAB, by contrast, feels rather like a corporate version of the hand-crafted veneers and brushed metallic touches that sit on top of the build-up. That’s why designers, manufacturers, airlines and journalists come here to Thomasberg, to see the impressive innovations at visual level.

But, rather like the Shapeshifter product, it’s what’s underneath that really matters, and here F/LIST has a dual proposition for the industry: either just as a trim and finish provider, or as a bigger player within a project.

“We're not just a material supplier, and I think this is a big differentiator, because just talking about, for example, our wood veneers, which are now finally approved: we just don't only deliver the veneer,” List-Nagl says. “We are the ones that create the full build-up, every layer. We know how to implement it on the cabinetry. I think the level and the amount of our content in the value chain is quite big.”

Inherently, the engineering and certification requirements become more strenuous moving from the private jet to commercial airline world, but experience in one does have some read-across to the other.

“We can offer them just delivering the decorative material, or the full build-up, or we do the whole monument, or we team up with some other partner so that we can deliver a fully integrated project together,” List-Nagl explains. “We are quite agile in our approach, because we don't say: this is our product, take it or leave it. We are open in whatever setup and requirement our customer or counterpart or airline has.”

Considering customisation versus volume during the certification crunch — and beyond the cabin

The extent to which seatmakers and airlines can work together to achieve maximum perceived customisation for passengers while requiring minimal seat certification changes is a major topic at the moment within the seats, cabins and wider passenger experience world.

This becomes, inherently, a question of volume when it comes to key elements of that customisation, especially towards the front of the aircraft — and, to an extent, even more so to the front of the business class cabin, where new studio class front-row business-plus suites are often missing that certain luxurious something to differentiate them from the seats in row 2 and back.

“Usually, other suppliers in commercial aviation are all looking for high volume. If we're talking about first and business class environments, we're talking about, I don't know, six to maybe ten private suites in an airliner,” List-Nagl says. “We are used to dealing with small volumes. We have all the toolings when it comes to all-lightweight construction. We always come from the from the low volume side, and I think again, this helps entering this the luxury segment, now, of the commercial airlines.”

But there’s a volume sweet spot for commercial aviation, List-Nagl says. A key difference between airframers and cabin designers in business aviation versus commercial aviation is that there is a point at which commercial aviation has the volume to amortise development costs, but where business aviation does not.

Some of this investment will be specific to a customer: the use of a specific pattern of a specific product on a specific part of a specific seat, say. But some will have wider read-across: once the full commercial aviation static and dynamic testing for a product in a particular use case is undertaken, F/LIST can offer a material in a different colour or pattern, for example.

If, say, one of its stone or metallic materials is used on a side table for a certain airline (as it, indeed, already is) it becomes lower risk for a designer to recommend its use on a side table on a different seatmaker’s product, or for a cocktail table, and so on.

At some point, that amortisation will be customer-related — a certain pattern of surface, for example, which will not have read-across to other seats, say — but some of it will have wider read-across.

And F/LIST is seeing marked interest in extending the aesthetics, feel and brand of airlines’ premium experience beyond the cabin, List-Nagl says.

“Airlines are also looking for 360-degree experiences for their passengers, so we could be a very good partner for them, not only working in their luxury areas — first and business class environment — but also in lounges at the airport or, creating an FBO experience in an aircraft lounge,” she notes, referencing the kind of fixed-base operator terminal that is seeing some interest in airlines looking to differentiate their first and studio classes on the ground.

“We could support them not only through the aircraft cabin, but through the rest of the passenger experience, to create that luxury experience in as many touch points as possible,” List-Nagl suggests, highlighting the benefits of bringing prospective customers out to Thomasberg and the F/LAB for blue-sky thinking.

“The ideas came out of this co-creation phase, where we just brainstorm what we could offer to the passenger, and one of the airlines came up with the idea of creating or designing the lounges in the same way as the first business class in their widebody aircraft.”

This kind of early partnership that moves beyond simply the traditional pathway of sub-supplier to seatmaker via design house is increasingly being seen as a prospective improvement to the way the industry works. Early involvement, here, is critical.

F/LIST identifies collaboration and co-creation spaces as a functional entry point into the product lifecycle

As materials suppliers have sought to differentiate their products and expertise over the last decade, one tool in their toolboxes is offering design and collaboration facilities, like Sekisui Kydex’s designLab and appLab. Benefits include not only rapid prototyping, but reducing the length of iteration cycles that might otherwise have required online meetings, FedExing materials, and overall cycles measured in weeks or longer.

F/LIST’s version is called F/LAB, and feels like something betwen a luxury car showroom and the Lufthansa First Class Terminal in Frankfurt.

During co-creation, List-Nagl explains, “the most critical questions are in terms of reliability, and in terms of commercial and technical feasibility,” but discussions also include how the collaboration will work.

“We are really seen as development partners, and this gives me a lot of validation and appreciation from the customer side, because we don't want ourselves to just be seen as a production partner,” she says, noting that F/LIST is willing to become deeply involved in the process. “I’m not even talking about the design concept or the technical feasibility, I'm really talking about how we set up a joint project team that creates a new cabin experience from A to Z, from concept phase to industrialisation phase until final delivery, plus even life cycle programs.”

There is a strong appetite within the industry to move beyond the concept of program management where ITCM (the Initial Technical Coordination Meeting) is the initial engagement with suppliers. This appetite is heightened by the ongoing struggles within the supply chain to deliver certified product on-time.

Fundamentally, she says, “when we enter in the early, earliest possible stage we have the responsibility — and the possibility — to create technically and commercially feasible solutions. When everything is set already, they just go for the cheapest price. Now we look for the best possible solution, the best possible process, the best possible way of collaborating, which we are really enjoying.”

F/LIST is strategic about its involvement here, in how it is looking up and down the supply chain — and even, looking at the lounge and terminal context, sideways. The company plans to achieve the necessary growth in scale without risking the expansion growing pains all too common in the industry.

Products like Shapeshifter are a link up the supply chain, creating major subassemblies to integrate into seats and cabins from other suppliers.

A link down the supply chain, meanwhile, is interiors composites joint venture Hilitech — the other partner is Austrian composites specialist Hintsteiner — led by List-Nagl’s husband, Manfred Nagl.

Hilitech is already providing composites to a major seatmaker, and the use of composites in the commercial aircraft cabin context to replace what might be a largely wooden buildup in the private jet cabin context is both a necessity and a benefit.

“To be very honest, we are forced to grow,” Katharina List-Nagl says. “There is no other way but growing because in a high salary and cost environment, like in Europe, being a production company, you just have to create a certain amount of volume in order to stay competitive.”

List-Nagl rejects the use of venture capital or wider investment, which she says wold be on offer, aiming instead to grow more organically.

“We want to grow in a healthy way, and we never want to compromise on quality — never — and we never want to compromise in our innovative power,” she explains. “We want to do the right strategic steps, because we have opportunities enough every day. We could say yes to all of them, which we don't do, because we try to find out which helps us rolling out our strategy, which helps us differentiate: not doing more of the same. What are — for customers, airlines — projects that set a new standard in the industry? This is what we are looking for.”

Reflecting on the time spent in Thomasberg, F/LIST and its approach feels like a very modern, high-tech, European way of doing business in an industry that can feel like it risks losing the human connection with what, after all, is a series of seating and interior products that are in physical and visual contact with humans for extended periods of time.

That human connection was on show throughout, including as our group of journalists readied to leave F/LIST HQ, when the friendly reception staff offered everyone a locally grown apple from a large container by the front desk. It was one of the best apples I’ve ever tasted.

F/LIST provided flights and accommodation in Vienna for The Up Front’s journalist for its media visit to Thomasberg and to attend the RedCabin summit, which F/LIST sponsored.